UPCorp is committed to providing exceptional precision industrial ultrasonic cleaning and liquid processing solutions to our customers by leveraging the latest in technology. Whatever your requirements for a commercial ultrasonic cleaner, we can provide you with the exact solution you need.

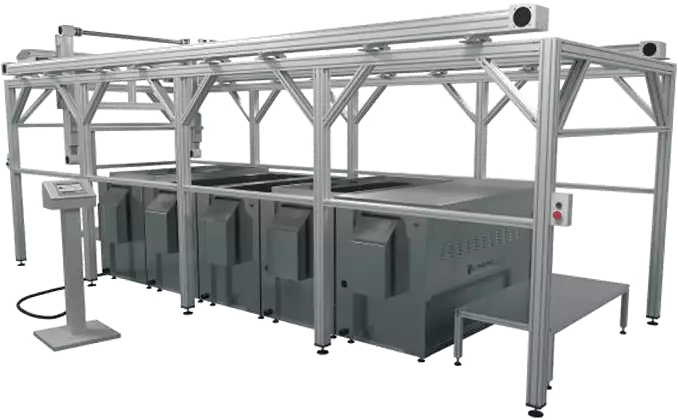

Featured Industrial Ultrasonic Cleaning Systems

Ultrasonic Cleaning Needs Aren’t the Same for Everyone

Let Ultrasonic Power Corporation design, develop, and deliver a custom industrial ultrasonic parts washer that meets your exact unique requirements. Our premium products are built using the highest quality materials and are constructed to your individual specifications.

Industries We Serve

As the premier manufacturer of industrial ultrasonic cleaning systems, we are proud of the wide variety of industries our equipment serves.

Ultrasonic Cleaning Applications

Depending on your application a few variations can be made in order to find the ultrasonic cleaning system that fits you.

Why Choose Ultrasonic Power Corp?

As a “Made in the USA” ultrasonic equipment company, we leverage the latest in technology to ensure our customers get the most effective and efficient ultrasonic cleaning machine solutions. Our products are built with highly durable stainless steel and will outlive and outperform anything else on the market. We provide fit-for-purpose technical assistance, components for preventative maintenance, training, and other support solutions. Our portfolio of products and services differentiates us as an innovative brand with the utmost integrity.

Working with UPCorp is a seamless process, from the moment you contact our team of experts to receipt of your precision cleaning system. And it doesn't stop there as we provide an industry-leading warranty as well as a range of post-purchase support and maintenance services. Find out today how UPCorp can help you improve your operations with a superior industrial ultrasonic cleaner.

Our Services & Differentiators

Cleaning Test

Send your parts to UPCorp for free evaluation and sample processing in our testing lab. You'll get them back promptly with a detailed process sheet showing how tests were conducted, suggestions for improving current processes, and recommended machinery. After our ultrasonic cleaning test services you will understand the benefits we offer... seeing is believing!

Financing

Need assistance in procuring your new industrial ultrasonic cleaner? We offer a variety of leasing options and can provide you with a speedy quote on your estimated monthly payment.