Aqueous Cleaning Solutions

Many industrial and professional organizations choose aqueous methods for their cleaning needs. Aqueous cleaning, particularly when combined with ultrasonics, is as effective as petroleum-based solvents – without the risks of solvent use.

Aqueous cleaning is versatile – it’s as good for delicate medical equipment as for grimy engine parts. But that versatility means that the cleaning solution must be prepared and used in the right way for each specific application.

Aqueous Cleaning with Ultrasonics

Solvents are sometimes needed to remove particularly tough contaminants from metal parts. But for most applications, ultrasonic cleaning is equally effective – and a safer, more environmentally friendly choice.

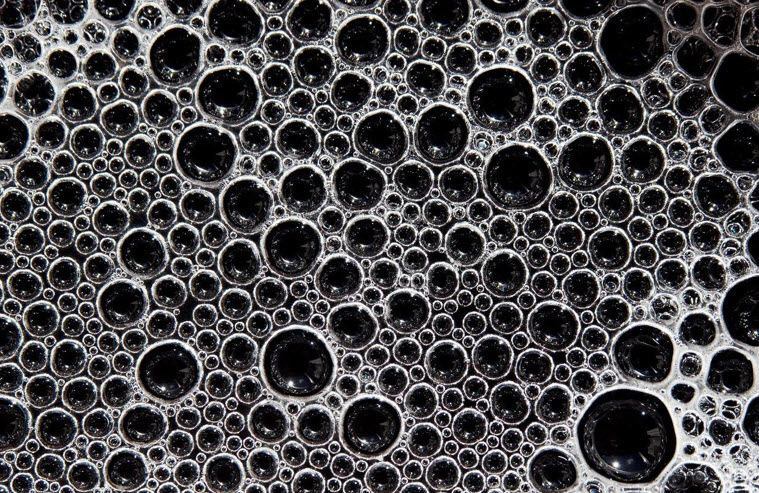

Ultrasonic aqueous cleaners use water, usually mixed with a specially designed detergent or cleaning agent. The solution is heated to an optimum temperature and ultrasound waves are applied to the ultrasonic bath.

The aqueous cleaning solution – or ultrasonic detergent – is a critical component in the cleaning process. A cleaning fluid makes contaminants easier to remove by dissolving soluble contaminants or acting as a wetting agent for insoluble contaminants. The solution is heated to accelerate and improve the cleaning process.

Choosing the Right Detergent for Your Aqueous Cleaner

The right detergent depends on the objects being cleaned and the contaminants that need to be removed.

The types of detergent used in aqueous ultrasonic cleaners are:

- Alkaline detergents

Most ultrasonic cleaning applications use a detergent with a pH between 10 and 12.5. This type of detergent removes a wide variety of contaminants from many types of materials. Highly caustic solutions can be used if more aggressive cleaning is required.

- Acidic Detergents

Cleaning fluids containing phosphoric acid are used for applications such as polishing instruments, cleaning electronic parts, and removing oxides or mineral deposits such as limescale.

- Enzymatic Solutions

Solutions containing enzymes are used in the pharmaceutical and food industries to remove organic contaminants, such as blood and starches.

- Deionized Water

Most applications benefit from using a detergent, but some delicate materials or lightly soiled objects can be cleaned using deionized water.

Using the Aqueous Cleaning Solution

Detergents and cleaning fluids must be thoroughly mixed with water to achieve the right concentration and prevent damage to the items being cleaned.

The ultrasonic bath needs to be heated to the optimum temperature for the chemical process to take place. Alkaline cleaning solutions require a temperature of 140°F. Some fluids with a high pH require higher temperatures.

Cleaning solutions can be reused multiple times. When they start to degrade, they need to be refreshed and used solutions disposed of carefully.

Cleaning Solutions for Pre-Cleaning and Rinsing

A pre-cleaning stage can loosen contaminants, prolong the life of the cleaning solution, and improve the efficiency of the cleaning process. Although water can be used for pre-cleaning, a detergent can be more efficient.

After cleaning, objects need to be rinsed one or more times to remove traces of cleaning solution and any loosened contaminants. Clean water is often sufficient for rinsing, but sometimes mild detergents or rinsing agents are used to completely remove any residue, inhibit rust, or prevent spotting on object surfaces.

Troubleshooting Your Aqueous Cleaning Solution

Using the wrong concentration of cleaning fluid or the wrong temperature can impair results.

Too high a concentration or temperature may cause damage to objects and lead to higher costs. Too low a concentration or temperature may involve longer or repeated cleaning cycles and less than perfect results.

If your aqueous cleaning process isn’t producing the expected results, here are some areas to investigate.

- Are you using the right detergent at the right concentration and temperature?

Check you’re using the right chemistry for your application and the solution is maintained at the optimum temperature throughout the cleaning process.

Try experimenting within the recommended concentration and temperature ranges to find the best combination for your application. If there’s no improvement, investigate whether a different detergent may be better suited for your application.

- Are you pre-cleaning or soaking objects first?

Sometimes a short soak, pressure spray, or pre-clean with a mild cleaning solution can have a significant impact on the overall cleaning results.

- Is your cleaning solution clean enough?

You don’t want to refresh your cleaning solution unnecessarily, but you won’t achieve good results if the solution is degraded. Experiment with different refresh cycles to find the optimum time for changing the cleaning solution.

You may also need to investigate other factors in your cleaning process. Check the physical components of your cleaner, such as the pump, filter, and tank, as well as the other key factors that affect the cleaning process, such as the cleaning cycle time.

Wrapping Up

The aqueous cleaning solution that you use in your ultrasonic cleaner plays a key role in the results you can achieve from your cleaner. It’s important to follow the manufacturer’s guidance or take expert advice on how to prepare and use the cleaning solution for your aqueous cleaner.

At UPC, we have a range of detergents for every application and guidance for how to choose the best one for your requirements.

If you have any questions, please feel free to get in touch so we can help you achieve the best results with your aqueous ultrasonic cleaner.