Ultrasonic Cleaning 101

Many industries and professions rely on ultrasonic technology for their cleaning needs – it’s precise, thorough, reliable, and environmentally friendly. In this guide, we give an insider’s view into everything you need to know about using ultrasonic cleaning for industrial and professional applications.

Contents:

The History and Science Behind Ultrasonic Cleaning Technology

What Can Be Cleaned in an Ultrasonic Cleaner?

What Can’t Be Cleaned in an Ultrasonic Cleaner?

Benefits of Ultrasonic Cleaning

Applications and Uses for Ultrasonic Cleaning

Key Industries for Ultrasonic Cleaning

Components of Ultrasonic Cleaners

The Ultrasonic Cleaning Process

Factors Affecting the Ultrasonic Cleaning Process

Best Practices and Maintenance for Ultrasonic Cleaners

Choosing the Right Ultrasonic Cleaner

Alternatives to Ultrasonic Cleaning

The History and Science Behind Ultrasonic Cleaning Technology

Back in the 6th century BC, Greek mathematician and philosopher Pythagoras began studying the science of sound. But it wasn’t until early in the 20th century that people discovered the special cleaning properties of ultrasound waves.

It became the start of the ultrasonic cleaning revolution.

During the 1930s and 1940s, researchers explored how to use ultrasonics to clean delicate instruments in laboratory settings. Commercial ultrasonic cleaners were introduced in the 1950s, mainly for cleaning jewelry and optical devices. During the next two decades, major advances in the technology brought larger, more efficient cleaners to other industries, including the medical, automotive, aerospace, and electronic sectors.

Ultrasonic cleaning gained a significant boost in popularity when the international Montreal Protocol came into force in 1989. The protocol – and other initiatives designed to protect the ozone layer – sought to phase out the solvents responsible for ozone depletion. This included the chlorofluorocarbons (CFCs) used for cleaning, particularly in the vapor degreasers that were common at the time in industrial cleaning processes.

As ultrasonic cleaning became more widely used, innovations focused on developing better cleaners, improving cleaning fluids and detergents, and extending the technology to new applications and industries.

Today, ultrasonic technology is a safe, environmentally friendly, and efficient cleaning method. It’s a critical step in the manufacturing and maintenance processes across many industries.

How Ultrasonic Cleaning Works

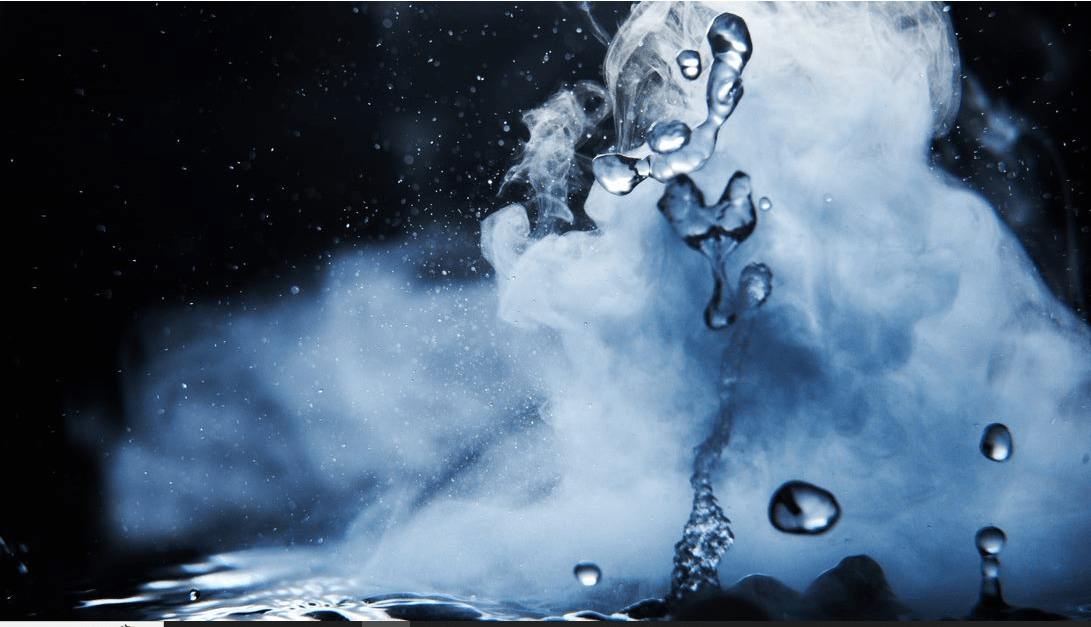

Ultrasonic cleaning works by using transducers to generate ultrasound waves that radiate through a cleaning solution containing the objects to be cleaned.

Transducers operate in a similar way to radio speakers, except they function at ultrasonic frequencies (usually 40kHz) and convert electrical energy into sound waves in a liquid rather than in air. The sound waves cause microscopic bubbles to form and burst in a process called cavitation. This action causes contaminants to lift away from the surface of the objects in the liquid.

What Is Cavitation in Ultrasonic Cleaning?

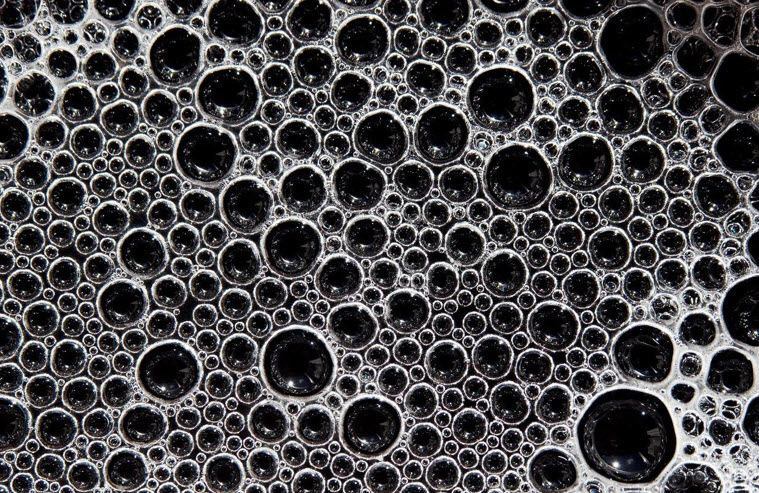

Cavitation is the process of tiny bubbles forming and collapsing when ultrasound waves move through a liquid.

The high frequency vibrations of the sound waves compress and expand the molecules in the liquid. The expansion phase causes microscopic cavitation bubbles to form. In the compression phase, the bubbles collapse in a process called implosion. As the bubbles implode, they send high-speed jets of hot liquid onto the surface of any objects in their path. This creates a constant scrubbing action that removes contaminants from the objects.

The bubbles can range in size from a few microns to around 100 microns in diameter – the largest ones similar in size to the width of a strand of hair or grain of table salt. The frequency of the ultrasound waves is the main factor affecting the size of the bubbles.

Ultrasound Waves

Sound wave frequency is measured in Hertz (Hz), with 1 Hz corresponding to one wave or cycle per second, and 1 kHz (kilohertz) corresponding to one thousand cycles per second. The sound waves used in ultrasonic cleaners are in the ultrasound range (above 20 kHz) – mostly above the range that is audible to humans (20 Hz – 20 kHz).

To human ears, the frequency of sound waves affects the pitch of the sound – the higher the frequency, the higher the pitch. In ultrasonic cleaners, the frequency of the ultrasound waves affects the size of the cavitation bubbles. With lower frequency ultrasound waves, bubbles have more time to grow. The larger the bubble, the more energy they release when they implode. The more energy produced, the more vigorous the cleaning action.

Higher frequency ultrasound waves create smaller bubbles. These bubbles can penetrate tiny crevasses and cracks – making it possible to clean hard-to-reach surfaces. The lower energy implosions are gentler, which is beneficial when cleaning delicate objects or materials that can be damaged by more vigorous scrubbing.

What Can Be Cleaned in an Ultrasonic Cleaner?

Ultrasonic cleaners provide a safe, non-abrasive way to remove many types of contaminants from a wide variety of materials.

Some materials require special care, such as a milder detergent or lower temperature. For best results and to avoid damage to the item being cleaned, it’s important to take expert advice, and follow the manufacturer’s guidelines to ensure compatibility between the cleaning solution, contaminant, and the item to be cleaned.

Materials Suitable for Ultrasonic Cleaning

| Material | Comment |

| Metals | Safe for most metals including steel, stainless steel, iron, aluminum, copper, brass, and titanium Softer metals may need special care to prevent cavitation erosion |

| Plastics and Composites | Safe for hard plastics and composite materials if the correct frequency and power levels are used |

| Glass | Safe for most types of glass including borosilicate, soda-lime, and lead glass |

| Ceramics | Safe for the advanced ceramics used in medical and electronic applications |

| Rubber and Silicones | Safe but the right cleaning fluid is important to avoid making the materials brittle |

| Precious Gems and Metals | Safe for cleaning most precious metals and stones, although some softer stones require careful handling |

| Textiles | Safe for some durable textiles to remove embedded dirt |

Contaminants Removed by Ultrasonic Cleaning

| Contaminant | Comment |

| Oils and Greases | Removes lubricants and greasy residues from machinery or automotive parts |

| Dust and Dirt | Particulate matter can be dislodged from surfaces, even from intricate parts and hard-to-reach places |

| Flux and Solder Paste | Common in electronics manufacturing, these can be cleaned from circuit boards and components |

| Biological Material | Blood, proteins, and other organic matter from medical instruments can be removed effectively |

| Rust and Oxidation | Metal parts prone to rusting can be restored through ultrasonic cleaning, often with the help of specific solutions that inhibit corrosion |

| Polishing Compounds | Residues from buffing and polishing operations in manufacturing jewelry or metal parts |

| Adhesives | Ultrasonic cleaning can remove adhesive residues left from labels, tapes, and glues |

| Mold Release Agents | These substances used in the molding process for plastics and rubbers can be stripped away |

| Carbon Deposits | Components like engine parts that accumulate carbon can be cleaned to restore functionality |

| Scale and Lime Deposits | Hard water can leave deposits on plumbing fixtures and components that are easily removed with ultrasonic cleaning |

| Paint and Coatings | Ultrasonic cleaning can strip certain types of paint or coatings, provided the correct solvent is used |

| Pharmaceutical and Cosmetic Residues | Leftover substances from production equipment can be cleaned to prevent cross-contamination |

What Can’t Be Cleaned in an Ultrasonic Cleaner?

| Material | Comment |

| Soft, porous materials | Materials like wood or paper can absorb the cleaning fluid and may be damaged by the intense cleaning action |

| Delicate items | Thin glass, certain gemstones (like opals, pearls, and emeralds), and some types of costume jewelry can be too fragile for ultrasonic cleaning |

| Some electronics | Microelectromechanical systems (MEMS) and other sensitive components may have parts dislodged or damaged by the cleaning action |

Benefits of Ultrasonic Cleaning

Precise, Thorough, and Gentle

Ultrasonic cleaning is one of the most effective ways to remove contaminants from objects, particularly those with intricate, delicate, or complex designs.

The microscopic bubbles created during cavitation can penetrate and clean the tiniest of crevices without causing damage. This precision cleaning is both thorough and non-abrasive, which preserves the integrity of the items being cleaned and prolongs their lifespans.

Save on Time and Labor

The cleaning cycle time with ultrasonic technology is usually much shorter than with traditional cleaning methods. And it’s reliable – no need for repeated cycles to fix areas that didn’t get cleaned properly the first time.

When factors such as ultrasound frequency and temperature have been optimized, the cleaning time is predictable and reliable, which is a major advantage in industrial processes where time and consistency are critical.

Ultrasonic cleaners can significantly reduce the need for labor to perform manual cleaning and scrubbing operations. The efficiency of ultrasonics in cleaning intricate parts reduces the need for disassembling parts before cleaning, again reducing the need for manual labor.

Automated cleaners streamline cleaning processes and reduce the potential for human error.

Read about saving time and labor with ultrasonic cleaning and how it reduces rework.

Safe and Environmentally Friendly

Sustainable, safe, and environmentally friendly work practices are essential in industries and professions today.

Solvents such as acetone, trichloroethylene (TCE) and methylene chloride (dichloromethane) are powerful agents for degreasing and cleaning, but present serious risks to the environment and workforce health. They are often subject to strict regulatory control and require a complicated and costly disposal process.

Ultrasonic cleaning is a great alternative to solvent-based cleaning. It delivers excellent results with milder, aqueous-based cleaning solutions that are cheaper and safer than the solvents used in other cleaning methods. It uses less water and energy compared to many traditional cleaning processes.

Cost-effective

Introducing ultrasonic cleaning to industrial and professional settings requires investment to acquire the machinery and optimize the cleaning process.

But ultrasonic technology saves on the time and labor required for cleaning. The equipment is long lasting and reliable, producing consistently high quality results over many years. It can deliver significant benefits in time, money, quality, extended lifespans for equipment, improved work environments and more.

Applications and Uses for Ultrasonic Cleaning

| Application | Comment |

| Parts | Individual components in machinery, equipment, or devices, ranging from small screws and bearings to larger mechanical assemblies). They can be made from various materials like metal, plastic, or composite. |

| Molds and dies | Tools used in manufacturing to shape, form, or cut materials into specific shapes and designs. They can have complex structures with small crevices and intricate designs. |

| Wire Cleaning | Wires and cables in sectors such as medical, aerospace, automotive, electronics, and scientific environments, must be kept meticulously clean. Complex surfaces or bundled wires present challenges for traditional cleaning methods. |

| Diesel Particulate Filters (DPFs) | Devices that remove diesel particulate matter or soot from the exhaust gas of diesel engines. Complex structures make it hard for traditional cleaning methods to reach all areas effectively. |

| Circuit boards | Cleanliness prevents issues such as short circuits, electrical failures, and corrosion. Complex layouts with intricate spaces where dust, flux residues, solder paste, fingerprint oils, and other contaminants can accumulate. |

| Anilox rolls | Rollers used in printing, particularly in flexographic (flexo) printing. Surface of rolls are covered with thousands of tiny, evenly spaced dimples or cells. Cleanliness is critical for guaranteeing a high-quality print process and maintaining the longevity of the rolls. |

| Flammable solvents | Safe cleaning with flammable solvents when there’s no choice but to use them. Cleaners require special modifications to ensure safe operation, primarily the risk of fire or explosion. |

| Passivation | Prepare items for passivation, a process of treating metal items with acid solution to create a protective oxide layer and protect surfaces from corrosion. Can also perform the passivation process. |

| Cerakote Application | Prepare items for applying Cerakote, a ceramic coating used in many applications. Items must be completely clean for successful application. |

Key Industries for Ultrasonic Cleaning

| Application | Comment |

| Aerospace and defense | Complex components with delicate geometries and precise tolerances. Examples include castings, housings, gear shafts, turbine blades, and landing gear. Made from a variety of materials including aluminum, stainless steel, Inconel alloys, and titanium. Contaminants include grease, oil, lubricants, carbon deposits, and oxidation. |

| Automotive | Components vary greatly in size and complexity. Examples include engine blocks, transmissions, carburetors, fuel injectors, Diesel Particulate Filters, and intake manifolds. Made from a variety of materials including metals, plastics, ceramics, and rubber. Contaminants include grease, oils, rust, brake dust, and carbon deposits. |

| Energy | Components vary greatly in size and complexity. Examples include stencils, screens, meshes, and solar panels as well as turbines, generators, and heat exchangers. Made from a variety of materials including many metals and alloys, ceramics, and plastics. Contaminants include oil, grease, sludge, and scale. |

| Firearms | Firearms vary greatly in size and contain complex components with intricate and hard-to-reach areas. Made from a variety of materials including gold, titanium, anodized aluminum. Contaminants that include dirt, carbon, lead, lubricant, and gunpowder. |

| Electronics | Components have intricate designs with small, delicate features. Made from a variety of materials including metals, plastics, and ceramics. Contaminants include flux, solder paste, marking inks, fingerprint oils, and other manufacturing byproducts. |

| Manufacturing and fabrication | Components vary greatly in size and complexity, many with intricate and hard-to-reach areas. Examples include machine parts and surface finishings. Made from aluminum, stainless and mild steel, titanium, Inconel alloys, and other materials. Contaminants include cutting fluids, lubricants, machining chips, oils, greases, metal shavings, dust, and chemical residues. |

| Music | Instruments vary greatly in size and complexity, many with intricate and hard-to-reach areas. Examples include brass and woodwind instruments. Made from brass, nickel, silverplate, and plastic. Contaminants include dirt and grime build up, oils, oxidation, calcium, grease, and other deposits, including mold and bacteria that can grow in moist areas. |

| Orthopedics and implants | Components often have complex shapes and textured surfaces. Made from stainless and mild steel, titanium, cobalt-chromium, Inconel alloys, and other materials. Contaminants include blood, tissue, bone fragments, and surgical residues. |

| Pharmaceutical and medical | Components vary greatly in size and complexity, many with intricate and hard-to-reach areas. Examples include medical instruments, equipment, and pharmaceutical components. Made from titanium, stainless steel, and various metal alloys, ceramics, plastics, and other materials. Contaminants include biological materials, residues from manufacturing processes, and other minute particles. |

Components of Ultrasonic Cleaners

Ultrasonic cleaners used in industrial and professional settings are sophisticated and powerful machines. Here we describe the key components of ultrasonic cleaning systems.

Read more about ultrasonic cleaner components.

Transducers for Ultrasonic Cleaners

Transducers are at the core of ultrasonic cleaners. They convert electrical energy from a generator into ultrasound waves that radiate through the liquid in a cleaning tank. This radiation causes the cavitation that cleans the objects in the tank.

Modern transducers are manufactured from lead zirconate titanate, a piezoelectric material which expands and contracts when electrical energy is applied to it. The rapid expansion and contraction of the material causes the adjacent surface to vibrate, introducing acoustic waves into the cleaning fluid in the tank.

The number of transducers required for an ultrasonic cleaner depends on the size and shape of the tank, the objects to be cleaned, and the contaminants that need to be removed. Industrial ultrasonic cleaners normally use modules or arrays of transducers. In large tanks, multiple transducer modules can be distributed across the tank to ensure more even cleaning.

Transducer modules can be fixed to a tank or immersed into a tank in a special container.

When transducers transmit ultrasound waves at a single frequency, standing waves can develop, affecting the quality of the cleaning. Advanced ultrasonic cleaners use transducers that transmit simultaneously across a spectrum of frequencies above and below their main frequency.

Read more about direct bonded transducers and immersible transducers.

Generators for Ultrasonic Cleaners

Generators in ultrasonic cleaners supply the electrical energy at the right frequency and power level for the transducers convert to ultrasound waves. Their performance is crucial to delivering an effective cleaning process.

For industrial and professional applications, it’s critical that generators are tough, durable, and reliable. They should be capable of supplying transducers that operate at multiple frequencies and should feature modulation sweep and power intensity control circuitry for optimum performance.

Industrial cleaning systems should be capable of using multiple generators to deliver enough power to handle very large tanks.

Tanks for Ultrasonic Cleaners

Ultrasonic cleaning tanks are specialized containers designed to hold the cleaning solution and the objects to be cleaned.

Different shapes and sizes of tank are available to meet the needs of a wide range of applications. They include tabletop models for small items to industrial-sized models for very large objects.

Usually made from stainless steel for durability and corrosion resistance, tanks must be suitable for the cleaning solution that will be used, which may be acidic or highly caustic. They must be able to withstand the ultrasonic cleaning power and frequency that will be applied.

Tanks usually include a heating element to warm the cleaning solution to the required temperature and may have sloped bottoms for easy draining and cleaning.

Pumps and Filtration Systems for Ultrasonic Cleaners

A filtration system in an ultrasonic cleaner removes contaminants and particles from the cleaning solution to prevent items from becoming re-contaminated as they’re removed from the tank. If allowed to settle, these residues can clog up a cleaning system.

With a good filtration system, the cleaning solution doesn’t need to be replaced as frequently and the transducers are protected from contamination by particles that might interfere with their operation.

A pump is needed to circulate the cleaning solution within the tank and through the filtration system.

As well as moving liquid through the filter to remove contaminants, a pump helps to ensure a consistent temperature in the tank and prevents particles and residue from settling at the bottom of the tank. A well-designed pump contributes to the overall efficiency of the ultrasonic cleaning process.

Sparger and Weir Systems for Ultrasonic Cleaners

Pumps and filtration systems are ideal for removing most contaminants from the cleaning solution. However, contaminants that are lighter than water, such as most greases and oils, will rise to the surface of the liquid. They may remain floating on the surface and re-contaminate items as the items are removed from the tank.

A sparger and weir system solves this problem.

A sparger pumps a stream of liquid across the surface of the cleaning solution, pushing contaminants over the end of the tank and into a weir. The cleaning liquid can then be filtered and returned to the cleaning tank.

Lifts for Ultrasonic Cleaners

Some industrial ultrasonic cleaners are fitted with a lift mechanism to raise and lower items in and out of the cleaning solution.

A lift is useful for moving very heavy or large objects. The movement during the cleaning process helps to ensure that all surfaces can be uniformly cleaned. Some lift mechanisms are designed to perform gentle agitation, which can further enhance the cleaning action.

Controls for Ultrasonic Cleaners

Ultrasonic cleaners used for industrial and professional applications should provide sophisticated controls so that the cleaning system can deliver the best results for the application.

An ultrasonic cleaner controller should provide the capability to control and fine-tune the power output, frequency, temperature, and cleaning cycle time. Advanced controllers are programmable and provide diagnostics, monitoring, and alert features.

Controllers can also be designed to manage filtration, sparger, and lift systems automatically on units that are fitted with these systems.

Read more about ultrasonic cleaning controllers and how they can improve ROI.

The Ultrasonic Cleaning Process

The stages required in an ultrasonic cleaning process depend on factors such as the items being cleaned, the contaminants to remove, and the level of cleanliness required.

Throughout the cleaning process, items need to be handled carefully to avoid recontamination. The ultrasonic cleaner must be filled with the correct cleaning solution and adjusted to have the right settings, such as frequency and power, for the specific application.

Ultrasonic Cleaning Process: Pre-Cleaning

Most ultrasonic cleaning applications don’t require pre-cleaning before the ultrasonic cleaning stage. However, pre-cleaning can be helpful for objects with loose dirt and debris, or with heavy soiling. It can prolong the life of the cleaning solution and improve the efficiency of the cleaning process.

Loose or superficial contaminants can be removed by wiping or brushing or by rinsing or spraying objects with water or a pre-cleaning solution. In some cases, soaking items or running an ultrasonic pre-cleaning cycle can help with removing strongly adhering contaminants.

Ultrasonic Cleaning Process: Cleaning

Items need to be fully immersed in the cleaning solution in the ultrasonic tank using a mesh basket, rack, or other means of suspension.

When the cleaning solution is at the right temperature, the ultrasonic cleaning cycle will run for the length of time that’s optimum for the application.

Ultrasonic Cleaning Process: Rinsing

Most objects need to be rinsed to remove traces of detergent or solvent and any loosened contaminants on the items.

Rinsing can be done by immersing or spraying items in a separate tank using clean water. For extra thorough rinsing, further rinsing cycles can be included in the process.

Using ultrasonics in the rinsing process is the most effective and efficient way to ensure that items are free from microscopic contaminants and residues.

Ultrasonic Cleaning Process: Drying

Some materials need to be dried as soon as cleaning and rinsing is complete to prevent water spots or corrosion, especially for metal parts.

Items can be air dried by blow drying with compressed air or by placing the items in a drying cabinet. Sensitive items may need controlled temperature or vacuum drying.

Ultrasonic Cleaning Process: Validation and Quality

Inspecting cleaned items is important to ensure the right level of cleanliness has been achieved. As well as visual inspection, a number of scientific methods can be used to assess the cleanliness of the parts.

Factors Affecting the Ultrasonic Cleaning Process

Ultrasonic cleaning is amazingly versatile.

Delicate medical instruments can be cleaned as effectively as engine components, despite the difference in size, materials, contaminants, and structure of the components. The key to high quality results is adjusting the factors that affect ultrasonic cleaning so that they work together to produce the best outcome.

Tuning an ultrasonic cleaning process to deliver the highest quality results can be complicated: adjusting one factor can mean changes are needed to others. It’s important to take expert advice to find the right combination of factors for your application.

Here we discuss the factors to consider when using an ultrasonic cleaner.

The Time Factor: How Long Does Ultrasonic Cleaning Take?

Ultrasonic cleaners work much faster to clean objects than other cleaning methods, often removing the contaminants in only a few minutes.

But it’s important to find the right time for each application. If the cleaning time is too short, objects may not be completely clear of contaminants at the end of the cycle. However, some materials can suffer from cavitation erosion if they’re exposed to ultrasonic cleaning for too long. This causes microscopic wear on the material’s surface.

The optimal cleaning time depends on the composition, size, and shape of the object, the type and amount of contamination, and the requirements for cleanliness.

Time is a key factor in achieving the best results from ultrasonic cleaning. It needs to be considered in relation to other factors, such as temperature and ultrasound frequency – adjusting one factor may require adjustments to others.

Read more about how time affects the ultrasonic cleaning process

The Temperature Factor: What Temperature Is Best for Ultrasonic Cleaning?

The temperature of the cleaning solution has a significant impact on the performance of the ultrasonic cleaning process.

If the temperature is too low, the cleaning process may not remove all contaminants from the objects. Higher temperatures can improve how ultrasonic waves are distributed in the tank and speed up chemical reactions within the cleaning solution, leading to a more effective cleaning process. However, they can also lower the force with which the scrubbing action occurs. Some materials or detergents may require lower temperatures for safety or to prevent damage.

Changing the temperature may require changes to the time and ultrasound frequency to achieve the best results from ultrasonic cleaning.

Read more about how temperature affects the ultrasonic cleaning process

The Frequency Factor: What Ultrasound Frequency is Best for Ultrasonic Cleaners?

- 25 kHz

The bubbles produced at 25 kHz frequency are significantly larger than the 40 kHz bubbles and produce a powerful force on implosion. This removes thick, stubborn, or sticky contaminants from large items. It’s often used to clean heavy mechanical equipment such as engine blocks, radiators, dies, and parts where the finish isn't a critical consideration.

- 40 kHz

For many applications, an ultrasonic frequency of 40kHz provides the most effective cleaning process. This frequency is used in around 95% of all industrial ultrasonic cleaning systems. The cavitation bubbles are small enough to penetrate tiny cracks and holes, powerful enough to remove stubborn contaminants and yet gentle enough for all but the most fragile materials.

- 68 kHz or 170 kHz

Ultrasonic cleaners operating at 68 kHz or 170 kHz provide exceptionally delicate and precise cleaning. These frequencies create sub-micron cavitation bubbles and can be used to clean pharmaceutical equipment, medical implants, titanium components, delicate electronics, and precision optics.

The Detergent Factor: What Cleaning Fluid Is Best for Ultrasonic Cleaners?

Using dish soap with a brush or cloth speeds up the process of cleaning dishes. In the same way, using a specially designed detergent in an ultrasonic cleaner makes the cleaning process quicker and more effective. The detergent loosens the contaminants on items to be cleaned and enables the ultrasonic system to increase the cavitation forces.

The right cleaning fluid for your application depends on the objects you’re cleaning and the contaminants you need to remove. Most providers of ultrasonic cleaners for industrial and professional use offer or recommend specific detergents and cleaning fluids to meet different requirements.

These are the main types of ultrasonic cleaning fluids:

- Alkaline Detergents are used to remove a wide variety of contaminants from many types of materials.

- Highly caustic solutions can be used if more aggressive cleaning is required, for example, to remove rust or strongly adhered contaminants.

- Acidic Detergents are used for applications such as polishing instruments, cleaning electronic parts, and removing oxides or mineral deposits such as limescale.

- Enzymatic Solutions break down organic materials such as blood and starches.

- Deionized Water can be used for delicate materials or very light soiling.

Cleaning fluids often need to be diluted and mixed thoroughly for maximum effect and to prevent damage to the items being cleaned.

Read more about how Cleaning Fluid affects the ultrasonic cleaning process

The Positioning Factor: How Should Objects be Positioned in Ultrasonic Cleaners?

For effective cleaning, objects need to be positioned carefully in the tank with respect to the where the transducers are located.

The load should be as close as possible to the transducers but not in contact with the bottom or sides of the tank or any immersible transducer containers. Contact with these surfaces impedes ultrasonic energy from reaching the load.

It’s best to suspend the load in the tank so that all surfaces of the objects can be cleaned effectively. Objects might need to be rotated during the cleaning process to ensure that all surfaces are cleaned thoroughly, especially if they have intricate configurations or stubborn contaminants. Air pockets can be removed by agitating or rotating the load.

Stainless steel mesh baskets are ideal, particularly when cleaning large objects or multiple objects at one time. In non-automated systems, it’s also possible to suspend an object in the tank using string or wire. Automated cleaners usually have a mechanical holding fixture that picks up a mesh basket containing the load. The holding fixture might be hooks or hangers, magnetic holders, rotating platforms or some other custom frame or fixture.

The Watts per Gallon Factor: What Power Do Ultrasonic Cleaners Require?

Watts per Gallon is the ratio of ultrasonic power to the volume of the cleaning solution in the tank.

The ratio affects how well the ultrasonic cleaning process works – too little power can result in ineffective cleaning, while too much power can lead to cavitation erosion and unnecessary energy costs.

More power results in more vigorous cavitation and a stronger cleaning effect. This may be required for items with heavy soiling or stubborn contaminants or where there is a stringent requirement for high levels of cleanliness. Less power with higher frequencies may be better for delicate objects.

There’s an inverse relationship between liquid volume and the power density required. A large tank may require a significantly lower Watts per Gallon ratio than smaller tanks.

The Load Factor: How Does the Load Affect the Ultrasonic Cleaning Process?

The ultrasonic cleaning process needs to be adjusted to handle the load to be cleaned, taking into account the size, shape, and density of the objects to be cleaned and the volume of the tank.

A dense load absorbs more ultrasonic energy, so more power or a longer cleaning time may be required. Objects with complex geometries may need rotation or agitation to ensure that all surfaces are cleaned effectively.

The load must be fully submerged in the cleaning solution and suspended so there’s no contact between the load and the sides or bottom of the tank or any immersible transducers. Objects should not overlap. It may be better to clean multiple objects in separate loads rather than one large load.

Best Practices and Maintenance for Ultrasonic Cleaners

With care and the right maintenance procedures, a high-quality ultrasonic cleaner can deliver excellent cleaning results for 10 to 15 years or even longer.

Best practice for maintenance is to follow a routine schedule, coupled with visual checks or scientific testing of objects, the cleaning solution, and the cleaner components. Advanced ultrasonic cleaners can monitor operation and raise alerts when action is required. For example, a controller can raise an alert if a change in cavitation activity levels is detected.

These are the typical maintenance procedures for ultrasonic cleaners.

Degassing Ultrasonic Cleaning Solutions

Most ultrasonic cleaning solutions contain air or other dissolved gases. During the cavitation process, bubbles that fill with these gases tend to resist collapse and remain suspended in the liquid. This reduces the efficiency of the cleaner.

Degassing is a process that removes unwanted gases from the cleaning solution. During the process, bubbles form containing the trapped gases and float to the surface where they pop and release the gases into the air. Degassing should be done whenever the tank is filled or topped up with fresh cleaning solution.

Some ultrasonic cleaners have a degas mode that delivers high intensity ultrasonic pulses to the cleaning solution. If a degas mode isn’t available, the cleaning solution in the tank can be left to stand for a number of hours before use or the cleaner can be run without any items in it for a number of minutes.

Changing the Ultrasonic Cleaning Solution

A cleaning solution can be used many times before it needs to be replaced.

The exact number of cleaning cycles depends on factors such as the type of contaminants being removed, the volume of items, the type of cleaning solution, and the level of cleanliness required.

The cleaning solution can be changed at regular intervals, when it looks cloudy, or if cleaning performance becomes degraded. For critical applications, scientific methods include testing conductivity or pH levels and refractometry or spectroscopic analysis.

The tank should be kept filled to the recommended level with cleaning solution for maximum efficiency and to prevent damage to the transducers.

Changing the Ultrasonic Cleaner Filter

The filter in an ultrasonic cleaner removes contaminants and particles from the cleaning solution. With a filter, the cleaner works more efficiently and the cleaning solution lasts longer before needing to be replaced.

The frequency for changing the filter depends on several factors including the type and level of contaminants being removed, the amount of cleaning performed, and the level of cleanliness required.

The filter can be changed at regular intervals or if it’s becoming clogged or accumulating debris. For critical applications, scientific testing methods include pressure differential measurement, flow rate monitoring, and particle counting.

Cleaning the Ultrasonic Cleaner Tank

The inside of the ultrasonic cleaner tank should be cleaned regularly to remove any residue or build-up of contaminants.

Cleaning should use a detergent that’s compatible with the tank and a soft brush or cloth to avoid scratching the surface.

Checking the Ultrasonic Cleaning System

To keep the ultrasonic cleaner performing at the highest level, it’s important to check that the whole system is working correctly and address any issues that arise promptly.

Specialized testing kits can be used to check that ultrasonic activity in the tank is functioning correctly. Regular inspections should be carried out to check for wear, corrosion, or other damage on the cleaner and electrical components. Testing and re-calibrating a cleaner may be necessary after some period of use.

Choosing the Right Ultrasonic Cleaner

Ultrasonic cleaners come in a variety of sizes and with different features to meet the requirements of specific applications.

The tank size should be just large enough for the load. Extra volume means more power is required to reach cavitation, resulting in increased costs. Cleaning systems can be configured with multiple tanks to handle the required cleaning process, including pre-cleaning, cleaning, rinsing, and drying.

Ultrasonic cleaners designed for industrial and professional use will usually include heaters, pump and filtration systems, and sparger and weir systems. They will typically have sophisticated, programmable controllers.

The number of transducer modules and generators required depends on the size of the tank and other factors such as the type and size of the load, the contaminants to be removed, and the level of cleanliness required.

These are the main sizes of cleaners used for industrial and professional applications.

Benchtop Ultrasonic Cleaners

Benchtop cleaners are compact and convenient. They are usually used for cleaning small parts with light to medium levels of contamination, for example, in medical, dental, and laboratory settings. Larger benchtop cleaners can be used for larger items or cleaning multiple items simultaneously.

Benchtop cleaners are available with different capacities, ranging from less than half a gallon to 50 gallons.

Large Ultrasonic Cleaners

Large ultrasonic cleaners have tanks that are designed to cater for very large items or loads and heavy-duty cleaning tasks. They are typically used in manufacturing, automotive, and aerospace industries. Large cleaner tanks typically have a capacity between 20 and 200 gallons.

Custom Ultrasonic Cleaners

Custom cleaners can be designed to meet specific requirements when standard-sized cleaners aren’t suitable. For example, custom systems may be needed to clean very large items or items with unique shapes or cleaning requirements.

Automated Ultrasonic Cleaners

Automated ultrasonic cleaners use overhead carriers to move a load automatically from one cleaning stage to the next. Automated systems can incorporate tanks of any size and can include tanks for all stages of the cleaning process.

An automated system is essential for industries that require streamlined assembly line operations with reliable and consistent results for every load.

Advanced automated systems can operate multiple loads for maximum efficiency.

Alternatives to Ultrasonic Cleaning

Ultrasonic cleaning has many advantages in a wide range of industries and professions, but there are alternatives.

Manual cleaning

Many items can be cleaned by washing or scrubbing by hand. This method may be feasible if items can be cleaned without the use of harmful chemicals and don’t need to meet stringent cleanliness standards.

Drawbacks to manual cleaning include the time and manual effort required, the potential for low quality results, and the likelihood that cleaning results won’t be repeatable and consistent.

Solvent-based cleaning

Cleaning with petroleum-based solvents can be effective. They can quickly dissolve residues such as grease, oil, grime, and carbon build-up.

The most serious drawback to solvent-based cleaning is that the solvents contain volatile organic compounds (VOCs), which are dangerous to health and the environment. They are particularly dangerous in vapor cleaners. Disposing of solvents after use is hazardous and expensive.

Ultrasonic cleaners can be modified to use solvents safely for those applications where only solvents are capable of meeting the cleaning requirements.

Aqueous Cleaners

A number of water-based cleaning methods can be used as an alternative to ultrasonic cleaning.

- Aqueous Spray Washers use nozzles within a cabinet to spray solutions at medium or high pressure at the parts to be cleaned. Cabinets come in a range of sizes and can include a rotating mechanism to ensure all surfaces are cleaned.

- Sink Top Aqueous Washers consist of a sink mounted on a drum. These washers are also called drum top aqueous washers. They can only clean a single or a small number of parts at one time and aren’t suitable for parts with heavy soiling or contamination.

- Rotary Drum Aqueous Washers consist of a rotating drum filled with cleaning solution. The parts are rotated to ensure all surfaces are cleaned. Large, high-power rotary drum cleaners can be used to clean very large parts or high volumes of small parts.

- Conveyor Aqueous Washers use a conveyor belt to move the parts through a cleaning solution before rinsing and drying. Conveyor washers can be manual or automated and are suitable for cleaning high volumes of parts at a steady stream with minimum handling.

The drawbacks of aqueous washing without ultrasonic technology are that cleaning usually takes longer and doesn’t offer the same level of precision cleaning or the high-quality cleaning results.

Read about advantages of ultrasonic cleaners over aqueous spray washers

Final Note

We hope we’ve provided everything you need to know about ultrasonic cleaning, how it works, the options available, and the advantages it brings for industrial and professional applications.