Automated Ultrasonic Cleaners

Ultrasonic Power Corporation offers high-performing automated ultrasonic cleaning systems that combine heavy-duty construction with high-tech control to deliver an extraordinary level of cleanliness.

A UPC automated industrial parts washer utilizes advanced ultrasonics wash systems, cutting-edge spray over immersion rinse systems, and state-of-the-art hot air dryer systems.

Utilize UPC's standard benchtop or console models or request custom size automatic parts washers built to your specifications.

Automated Bench Top Ultrasonic Systems

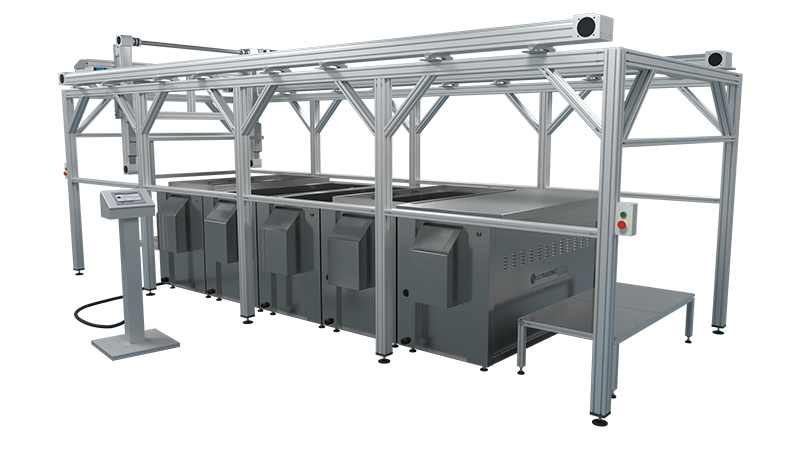

Automated LargeTank Ultrasonic Systems

Trusted by the Best

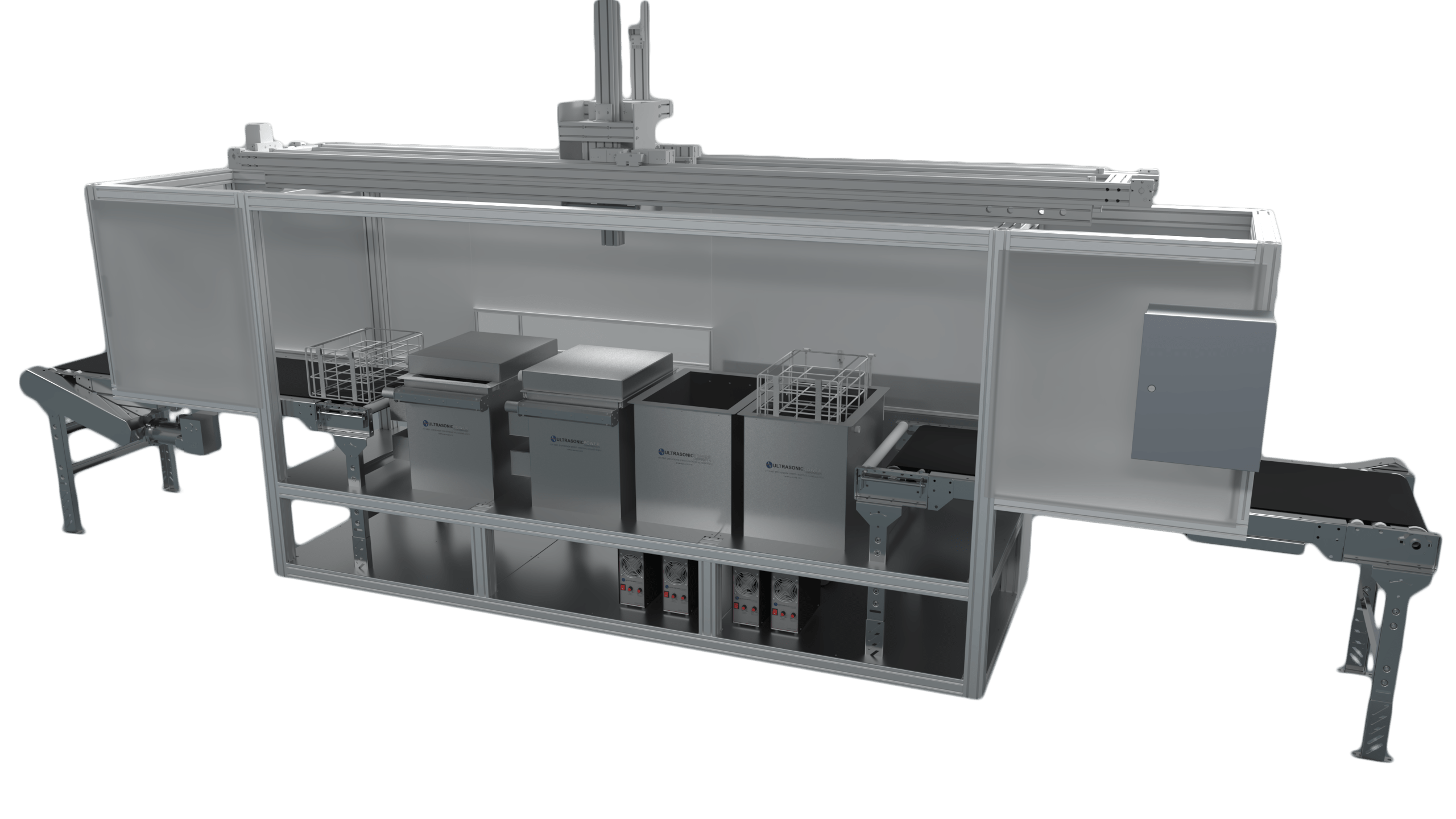

Three Tank Automated Wash, Rinse, and Dry Ultrasonic Cleaning System

Four Tank Automated Wash, Rinse, Spray Rinse, Dry

Key Benefits of an Automated Ultrasonic Cleaner

Some ultrasonic cleaning applications require high throughput and even continuous processing. For parts washing, it makes sense to utilize an automated industrial ultrasonic cleaner that requires minimal manual input. UPCorp has designed a range of systems that enable our customers to speed up ultrasonic cleaning and passivation processes, minimize equipment downtime, and drastically reduce the number of man hours required.

Not only does an automated parts washer ensure all equipment undergoes precision cleaning, but it also frees up staff for other tasks, improving efficiency and productivity. Plus, an ultrasonic parts washer uses an aqueous solvent, improving safety and environmental-friendliness.

Why Choose a UPCorp Automated Ultrasonic Cleaner?

Every UPCorp multi-tank ultrasonic cleaner adheres to the highest standards and is constructed using premium materials. We design and manufacture products in the USA but ship globally. All products are backed by our industry-leading warranty.

We tailor your automated ultrasonic cleaner to your exact needs, depending on size, number of stages, and other key factors. Both floor and benchtop systems are available.

Unsure of which type of ultrasonic cleaning machine you need for parts cleaning? Our experts are always on hand to offer as much advice as you need.

How does an automated ultrasonic cleaning system work?

An automatic parts washer makes parts cleaning a breeze. In automatic parts washers, an overhead carrier passes standard baskets through various cleaning stages. Basket positioners and sensors load and unload stations. Sonic Touch® II - a highly-advanced HMI system developed by Ultrasonic Power Corporation - controls the system.

What is Sonic Touch®II?

Sonic Touch® II is a multifunctional digital panel for controlling and viewing system functions like time, temperature, 7-day heat time, pump and filter, ultrasonic intensity, low liquid level, and the SOVI® diagnostic system. Sonic Touch® II also adds "Open Technologies" which includes functions like text messaging and e-mail. This provides the unique ability to constantly monitor the parts washing system and send alerts to a supervisor or even the manufacturer (if desired) for scheduled maintenance or troubleshooting.

What is an automated aqueous parts washer?

An aqueous parts washer is a cleaning system that uses an aqueous-based cleaning solution instead of a harsher solvent. Although petroleum-based solvents such as mineral spirits and other chlorinated solvents are effective at parts washing, they are expensive and represent health and environment concerns. An ultrasonic automated parts washer uses an aqueous solvent which is more effective and safe, and better for the environment.

What is an immersion parts washer?

An immersion parts washer is a parts cleaning unit in which the part to be cleaned is fully immersed in a solution. Ultrasonic automatic parts washers are a type of immersion system. These are ideal for cleaning industrial parts, automotive parts, and lots more.

What detergents are used in automated ultrasonic washers?

The detergent you use in your automated ultrasonic cleaning system will depend on the type of parts you are cleaning. For example, if you're using your ultrasonic cleaning tank for general cleaning, a mildly alkaline detergent will be most suitable. For more strongly adhered contaminants, highly caustic cleaners may be more appropriate.

How many stages are there in an automated ultrasonic cleaner?

A UPCorp ultrasonic cleaning system can be customized to your needs, but typical stages include washing, rinsing, and drying. In some cases, an additional rinse cycle may be required. In automated systems, you simply have a separate tank for each stage and baskets are automatically transferred from one tank to the next.