Blog

.png)

In the fourth part of our “basic concerns with ultrasonic cleaning” series, find out how the position of the transducers and load in the cleaning tank can affect your ultrasonic cleaning application.

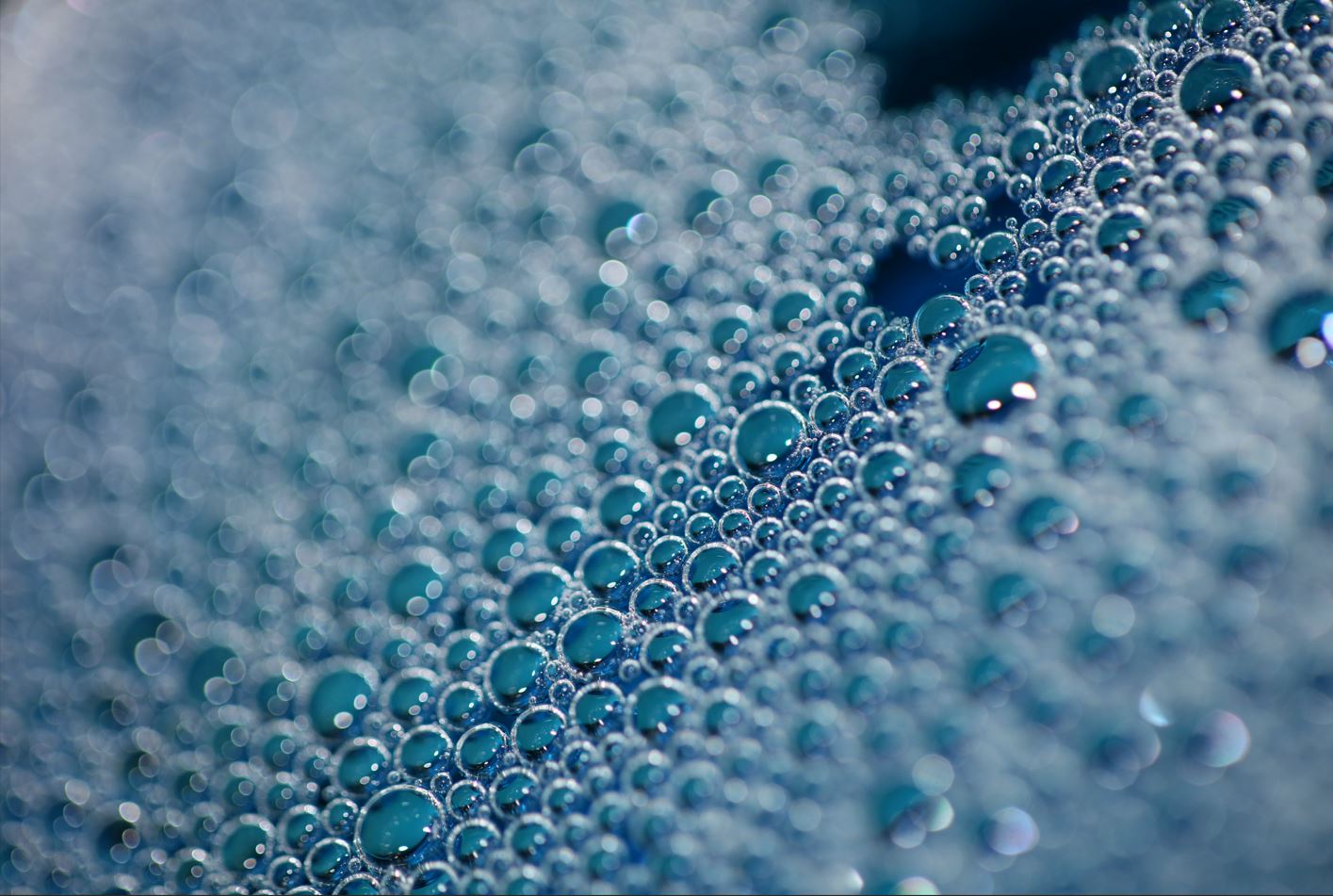

In the third part of our “basic concerns with ultrasonic cleaning” series, find out how the cleaning fluid you use can affect your ultrasonic cleaning application.

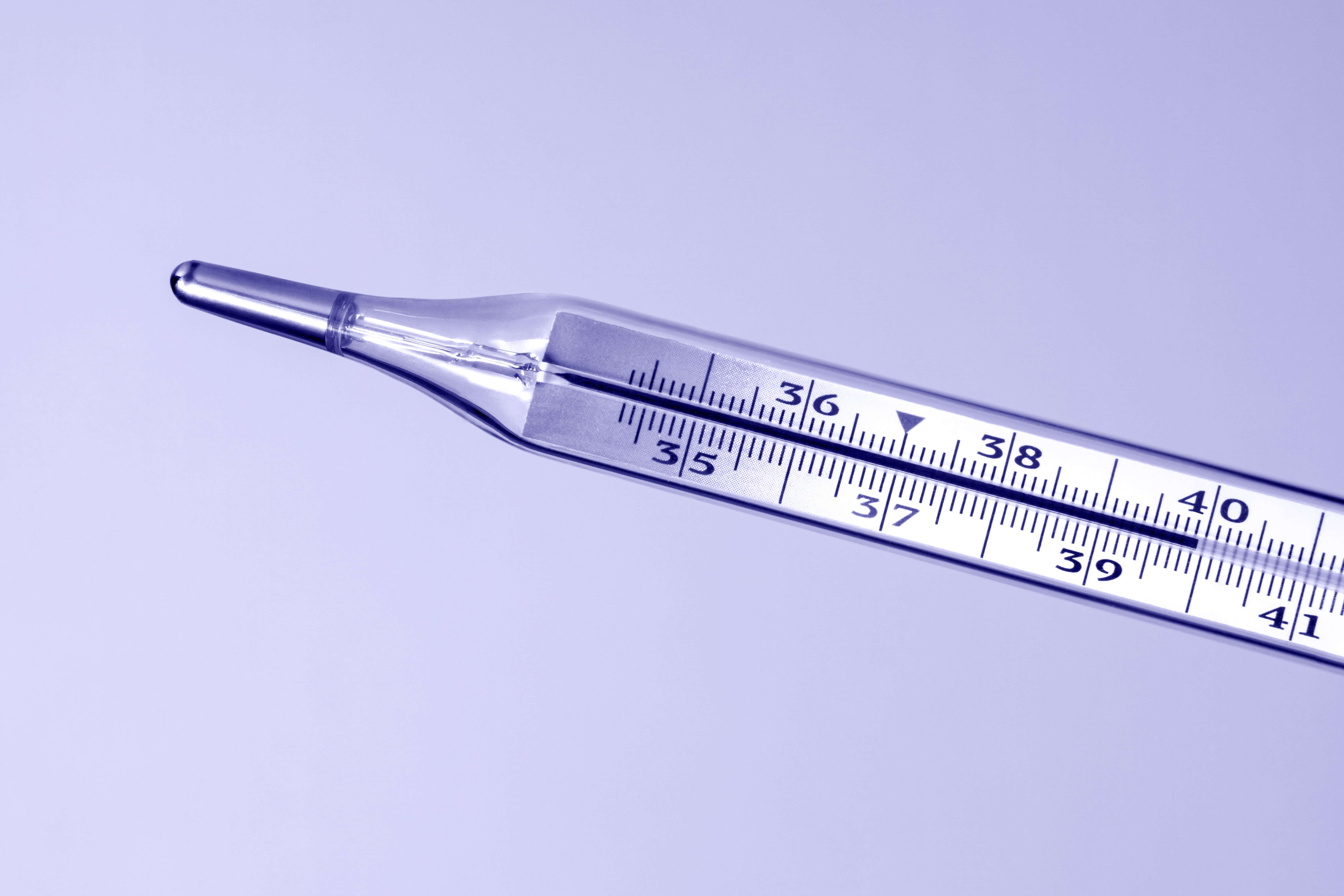

In the second part of our basic concerns with ultrasonic cleaning series, find out how temperature impacts your ultrasonic cleaning application.

The aqueous cleaning solution you use in your aqueous cleaner has a big impact on the results – find out why and how to choose the best one for your application

Read our 101 guide for everything you need to know about ultrasonic cleaning for industrial and professional applications

This series explores the key factors to consider when designing an ultrasonic cleaning process. In part 1, find out how cleaning time can impact results.

There are so many options when it comes to the range of ultrasonic units available. Find out how to select the ideal model.

.png)

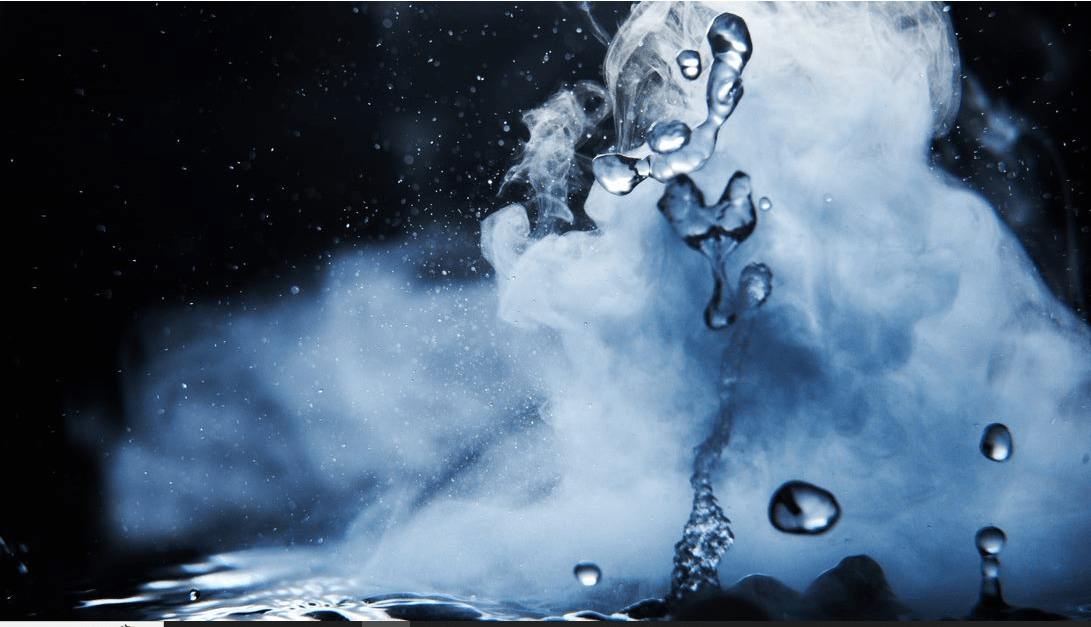

Wondering how an ultrasonic cleaner works? Discover the different components of an ultrasonic cleaner and exactly how it achieves precision cleaning.

Want to avoid purchasing a whole new ultrasonic cleaning system? An immersible ultrasonic transducer offers a convenient alternative.

Heat is an important part of the ultrasonic cleaning process. Find out more about heated ultrasonic cleaners and digital ultrasonic cleaners.

Searching for the most effective aqueous cleaning method? Find out about the highly effective aqueous ultrasonic cleaning system.

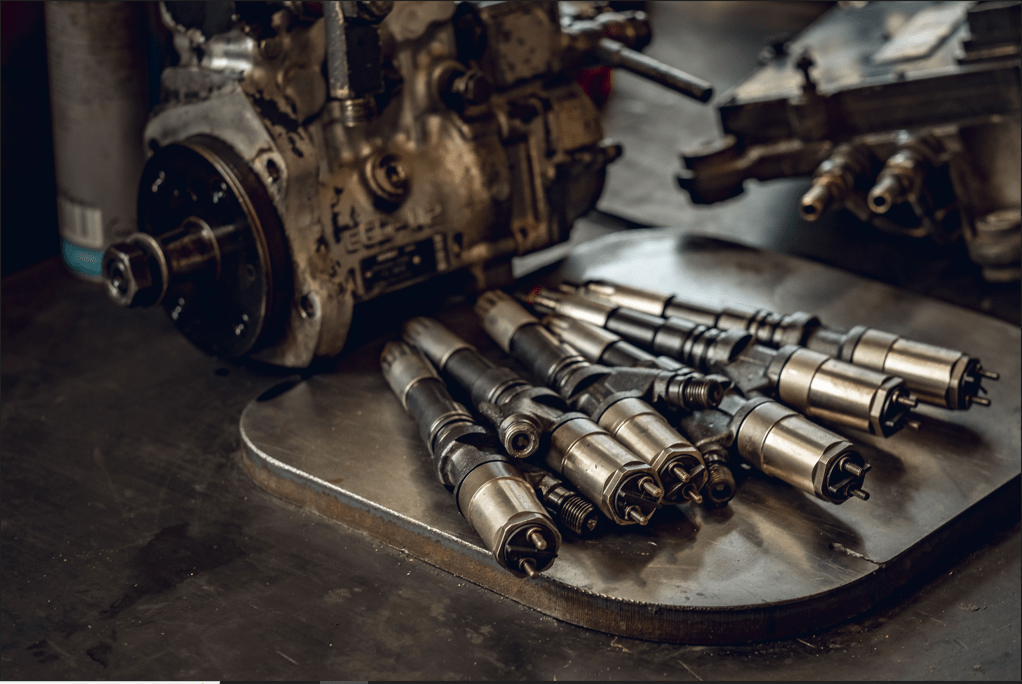

Looking for the ideal cleaning method for automotive parts? Find out about the benefits of ultrasonic fuel injector cleaning.