Basic Concerns with Ultrasonic Cleaning | Part 2: Temperature

Ultrasonic cleaning is a versatile method for precision cleaning of a broad range of objects. While it involves a simple process, there are several factors that need to be considered to ensure the best results. In this series of blogs, we take a look at the key concerns to keep in mind when using an ultrasonic cleaning system.

In the first part of the series, we explored the variable of time, which is important to ensure you get thorough cleaning without damaging components. In this article, we'll examine temperature. Temperature is a critical factor when it comes to ultrasonic cleaning, as it can have a significant impact on the effectiveness of the cleaning process.

Factors Affecting Ideal Cleaning Temperature

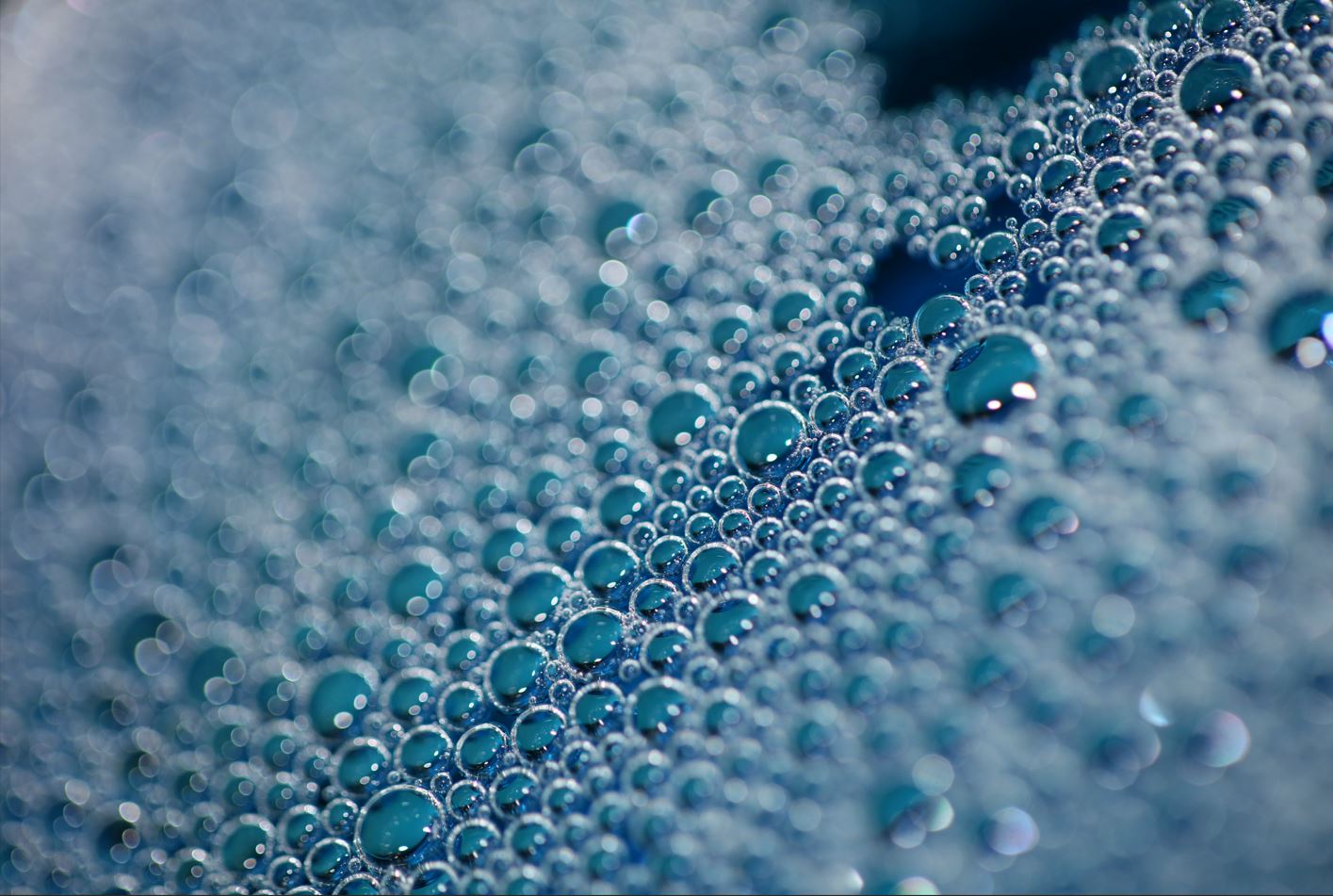

Ultrasonic cleaning is a highly effective cleaning process that uses high-frequency sound waves to agitate a cleaning solution, creating tiny bubbles that help remove contaminants from various surfaces. The ideal cleaning temperature can vary depending on a number of different factors, including the type of cleaning solution, the materials being cleaned, and the level of surface contamination.

Generally speaking, higher temperatures are more effective at removing contaminants, as they can help speed up the chemical reactions within the cleaning solution. For instance, some high pH solutions will require higher temperatures to enhance the chemistry's synergistic effect.

Typically, ultrasonic cleaning in an aqueous solution is optimum at 140°F, although theory suggests that a temperature of 65% of the boiling temperature of the cleaning solution should be ideal.

Risks of Using the Wrong Temperature

Using the wrong temperature can have several negative consequences when it comes to ultrasonic cleaning. If the temperature is too low, the cleaning process may not be effective enough to remove all of the contaminants from the surfaces being cleaned. This can result in having to run multiple cleaning cycles to achieve the desired level of cleanliness.

Higher temperatures can improve the distribution of ultrasonic waves within the tank. However, they can also lower the force with which the scrubbing action occurs. As such, it's essential to strike the ideal balance.

In addition to the risks associated with using the wrong temperature, it is also important to note that the temperature of the cleaning solution can impact the safety of the cleaning process. If the temperature is too high, it can increase the risk of burns or other injuries to the operator. Additionally, if the temperature is too low, it may not be effective enough to adequately clean the surfaces, potentially leading to contamination or other safety issues.

Wrapping Up

Using the right cleaning fluid in the right way is a critical factor to gain the best results from ultrasonic cleaning.

UPC provides a range of detergents for use with ultrasonic power cleaners and guidance on how to choose the best one for your requirements.

Do you need help designing your ideal ultrasonic cleaning application? Get in touch today! And remember to look out for the next post in this series in which we explore how the position of the transducer affects the cleaning process.

Ultrasonic Cleaners for Rent

We offer a range of our most popular ultrasonic cleaners for rent on a 30-day try-before-you-buy basis or as a long-term rental option.